Windows & doors manufacturer

Download

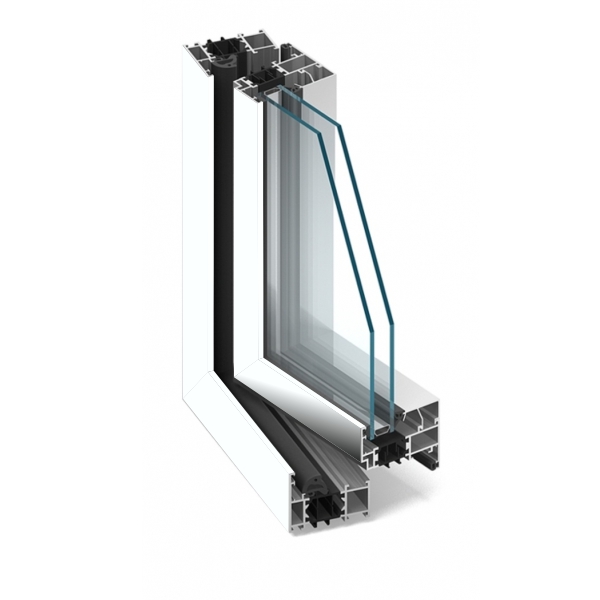

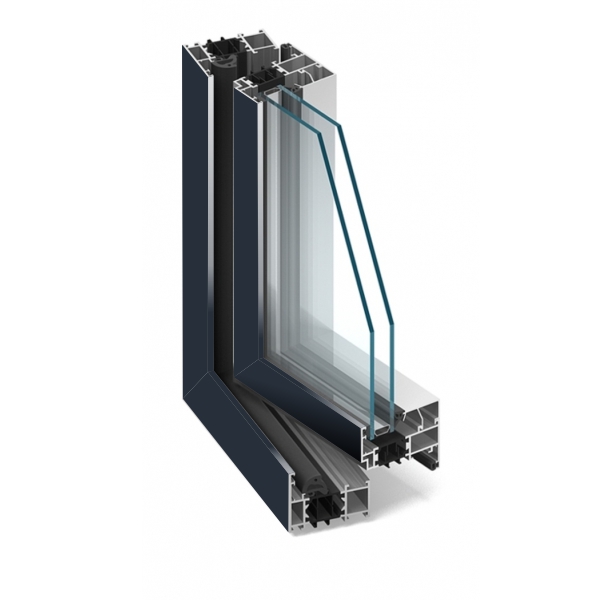

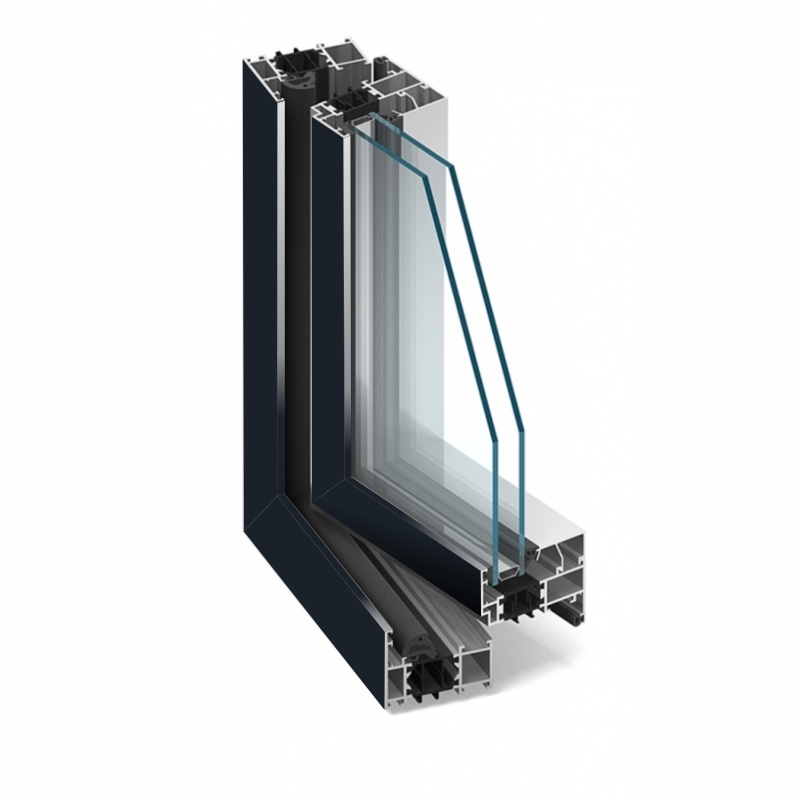

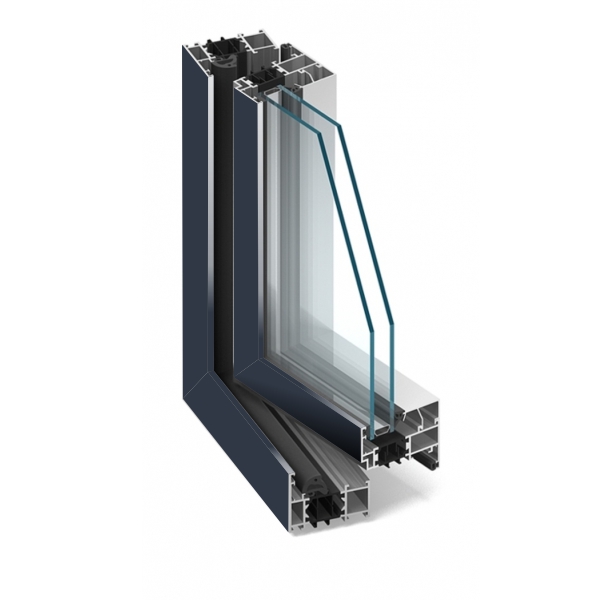

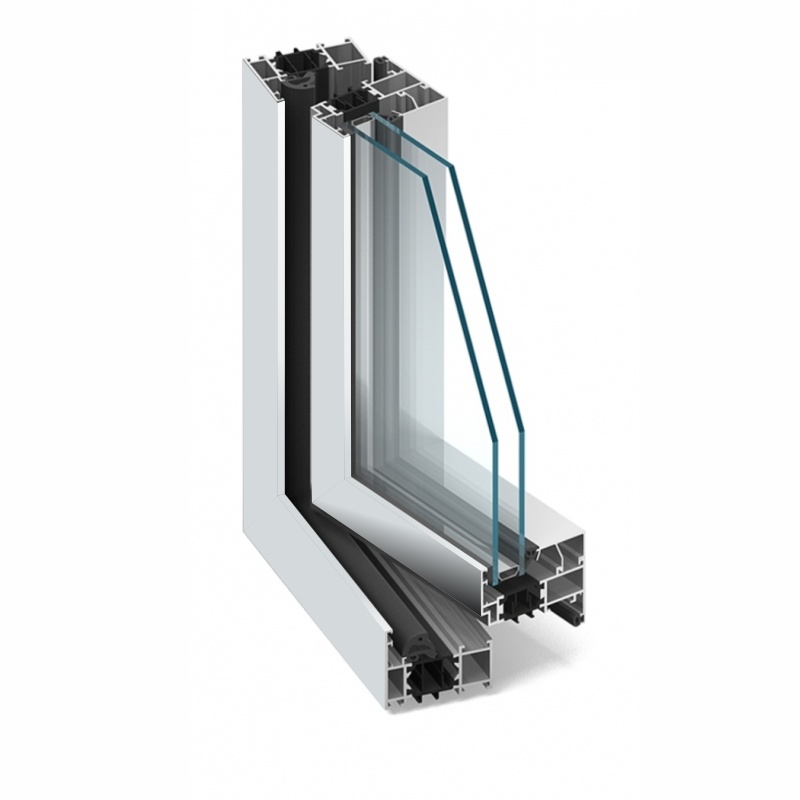

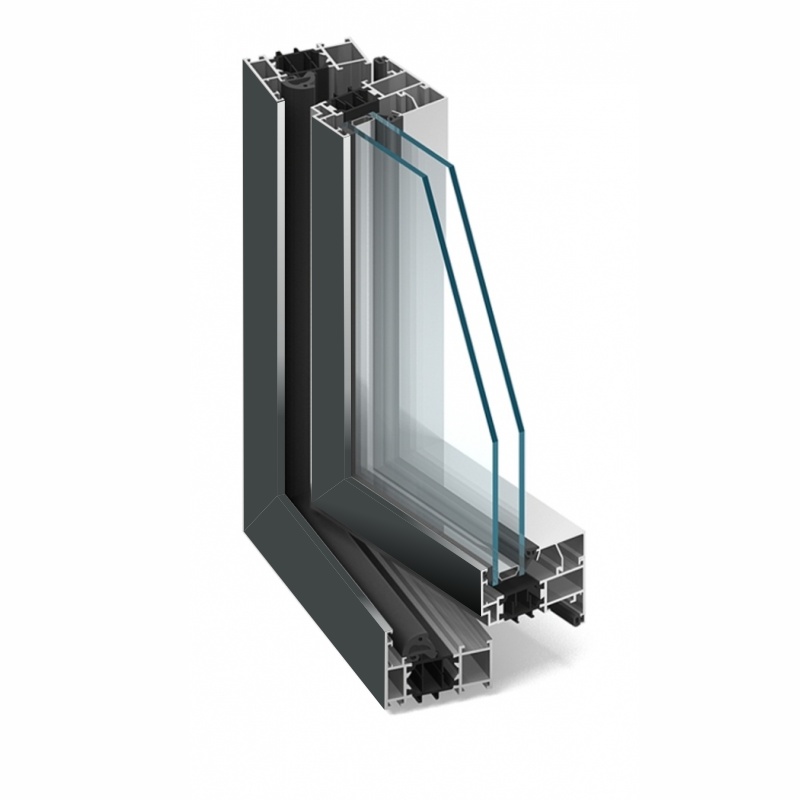

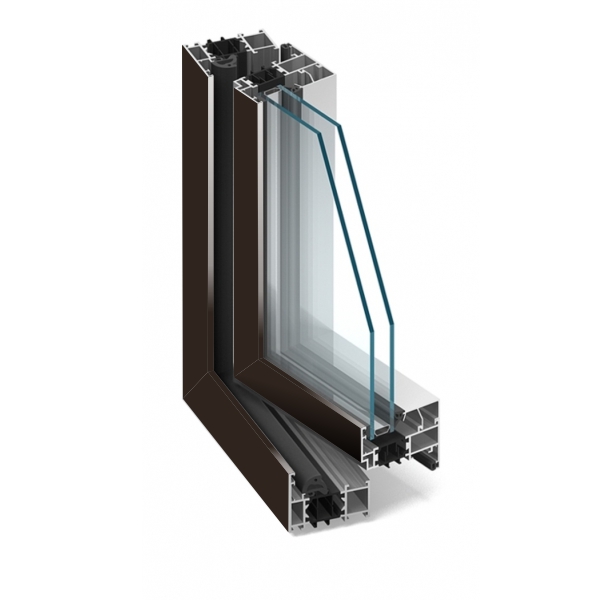

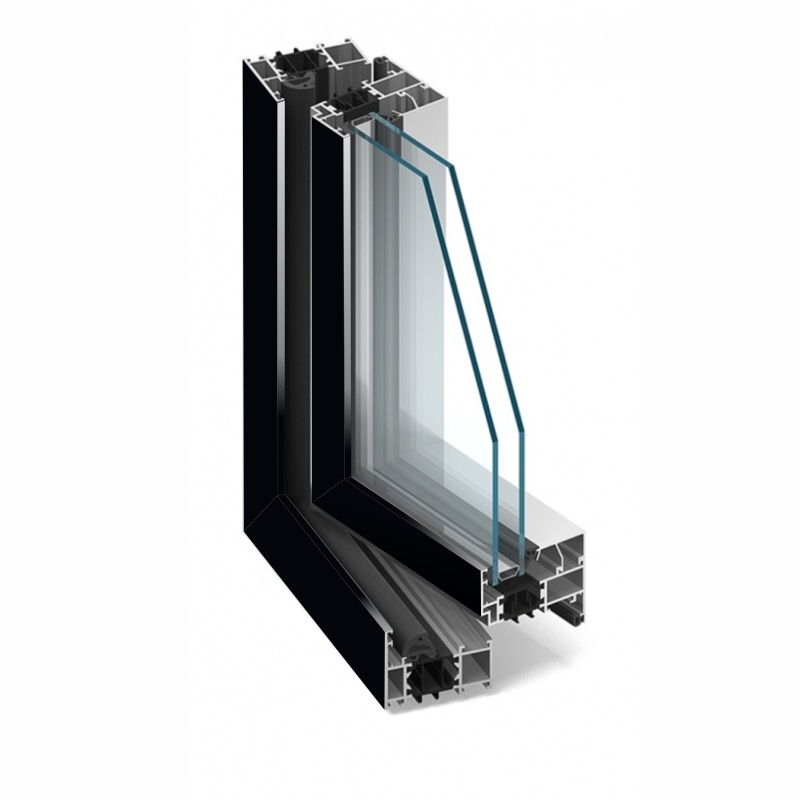

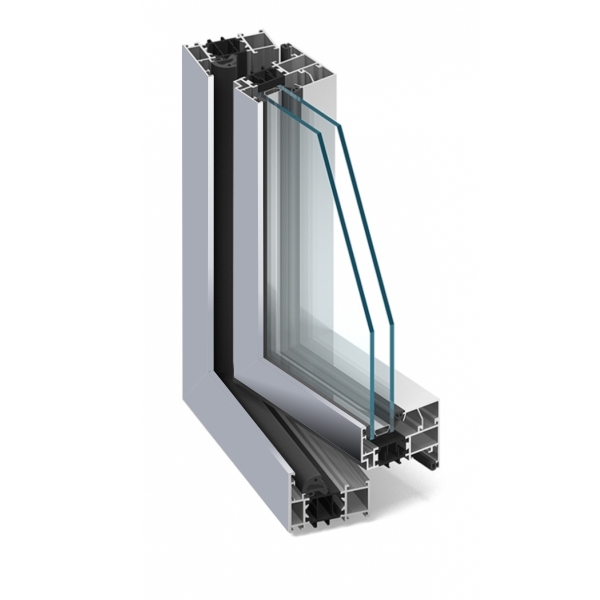

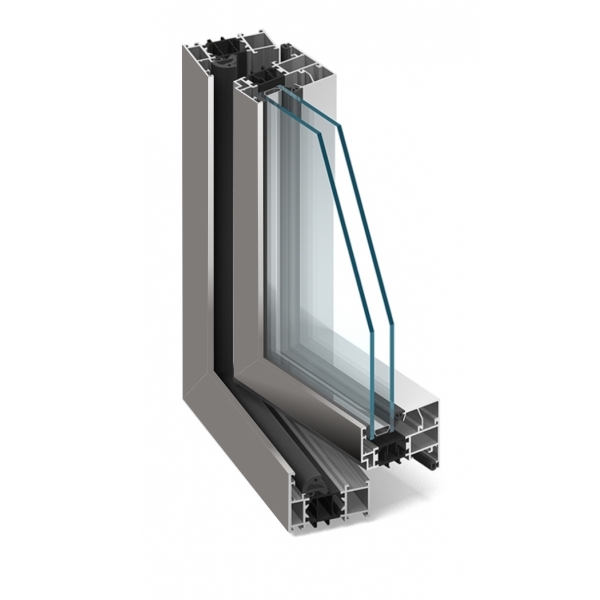

ALUPROF MB-70 – system with thermal and acoustic insulation

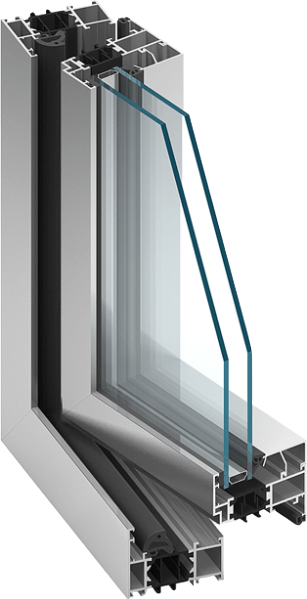

sets of glass panel : from 21 mm to 57 mm (window casements) and from 12 mm to 48 mm (fixed windows)

Uw up to 0,96 W/m2 K

Uw refers to the heat loss of the entire window – the lower, the better. The shown Uw value is calculated with the glazing Ug=0,5 W/m2 K for the standard window size (1,23 m x 1,48 m).

The structural depth of the window sections: 70 mm (frames) and 79 mm (casement)

three-chamber structure

MB-70 is a modern aluminium system intended for realizations of exterior architectural building elements requiring thermal and acoustic insulation, such as: various types of windows, doors, vestibules, display windows or spatial structures.

The depths of casement and frame sections give the effect of one surface from the exterior side after closing – in the case of the window, and the facing effect to the surface of casement and frames – in the case of doors.

Shape of the profiles allows achieving slender and resistant window and door structures.

The MB-70 system is characterized by a very low value of the overall heat-transfer coefficient Uf, thanks to application of the thermal breaks and gaskets. This is of a great significance in the times of increasing demands for the energy management and the environment protection. The value of heat transfer coefficient for constructions of the MB-70 system – depending on the applied profiles and accessories – ranges between 1.5 and 2.39 W/m2K.

In this system, the profiled “omega”-shaped thermal breaks are applied, of a width equal to 34 mm (windows) and 24 mm (doors), made from polyamide reinforced with fibreglass. The offered shape of thermal breaks increases the profile rigidity as compared to flat breaks and facilitates the section drainage, ensuring the appropriate thermal insulation in all atmospheric conditions at the same time.

The thermal breaks applied in the windows have additional gaskets at the joining point with the sections, as well as tongues dividing the chamber between the internal and external aluminium sections into three parts.

The tightness is ensured thanks to using the special gaskets made of two-component EPDM synthetic rubber: solid and cellular, which guarantees its ageing resistance during the long-lasting exploitation, as well as very good thermal insulation.

Owing to the application of, among others, thermal breaks of such shapes, it is not necessary to fill the space between them with polyurethane foam or foamed styrene inserts, in order to increase their thermal insulation.

A wide choice of colours in the standard palette makes it possible to meet the needs of our most demanding customers.

Colour Palette

All aluminium profiles are available in the wide colour palette. Below we present the standard colours, but of course the palette can be increased by all colours from RAL palette or wood-colour ADEC coatings.

* We also offer a wide range of non-standard colors. Aluminum windows are available in practically any color from the RAL palette (structure or smooth). We also offer a palette of ADEC wood-effect colors – available in the “Download” tab.

RAL 7016 Anthracite Grey

RAL 7021 Black grey

RAL 7024 Graphite Grey

RAL 7035 Light grey

RAL 7043 Traffic grey B

RAL 8019 Brown

RAL 9005 Jet black

RAL 9006 Silver

RAL 9007 Dark Silver

RAL 9016 White